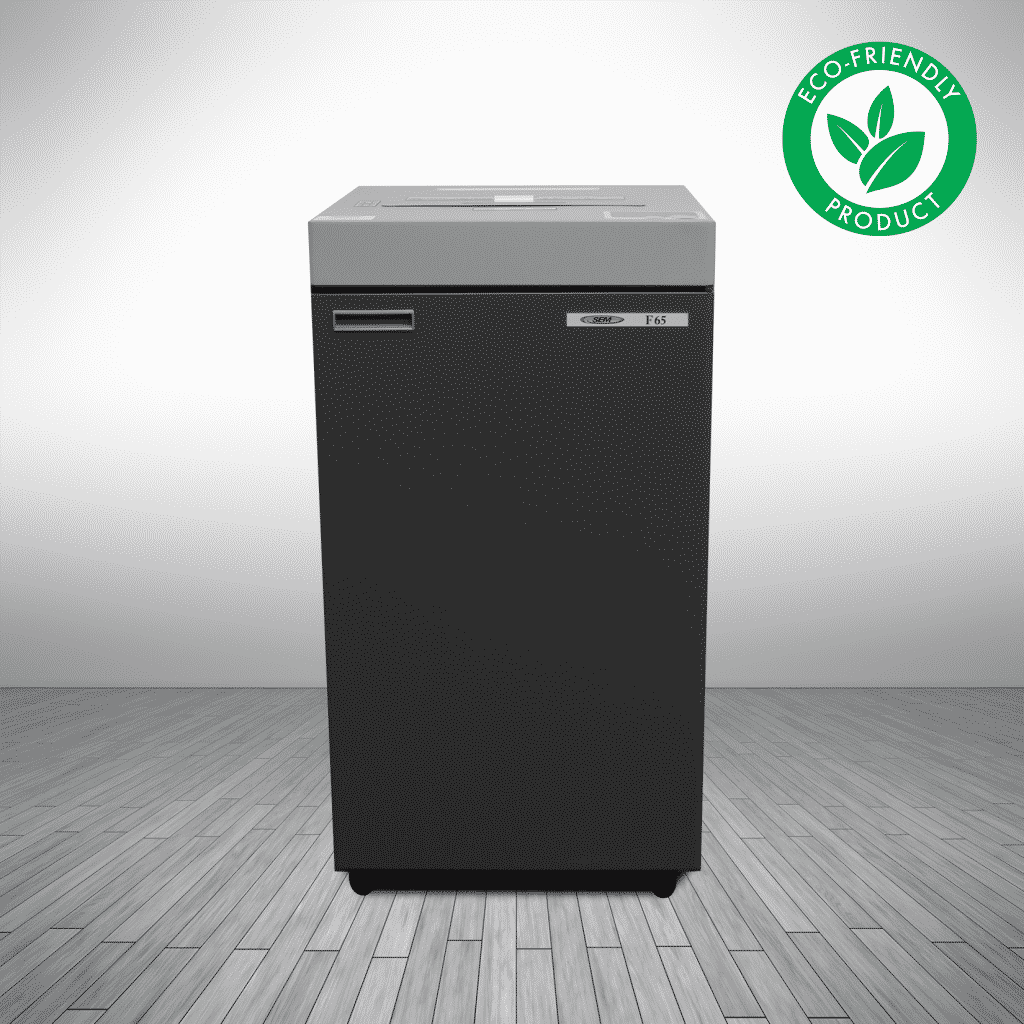

The F65 might sound like some next gen state of the art jet fighter, but what the F65 lacks in maneuverability and take-off speed it more than makes up for in HUGE shredding capacity for an office-sized shredder.

The F65 might sound like some next gen state of the art jet fighter, but what the F65 lacks in maneuverability and take-off speed it more than makes up for in HUGE shredding capacity for an office-sized shredder.

If you have a target rich environment (have a lot to shred), then this is our vote for best office shredder for non-class environments. It can shred up to 65 sheets of paper at a time to DIN Level P-4, as well as credit cards, CD/DVDs/BDs and will also accept paper clips and staples. Normally to get that kind of sheet capacity, you would have to move up to a larger, more expensive central system requiring 3-phase power. The F65 operates on 115-120V/15Amp power and requires no special outlets, so you can use it anywhere.

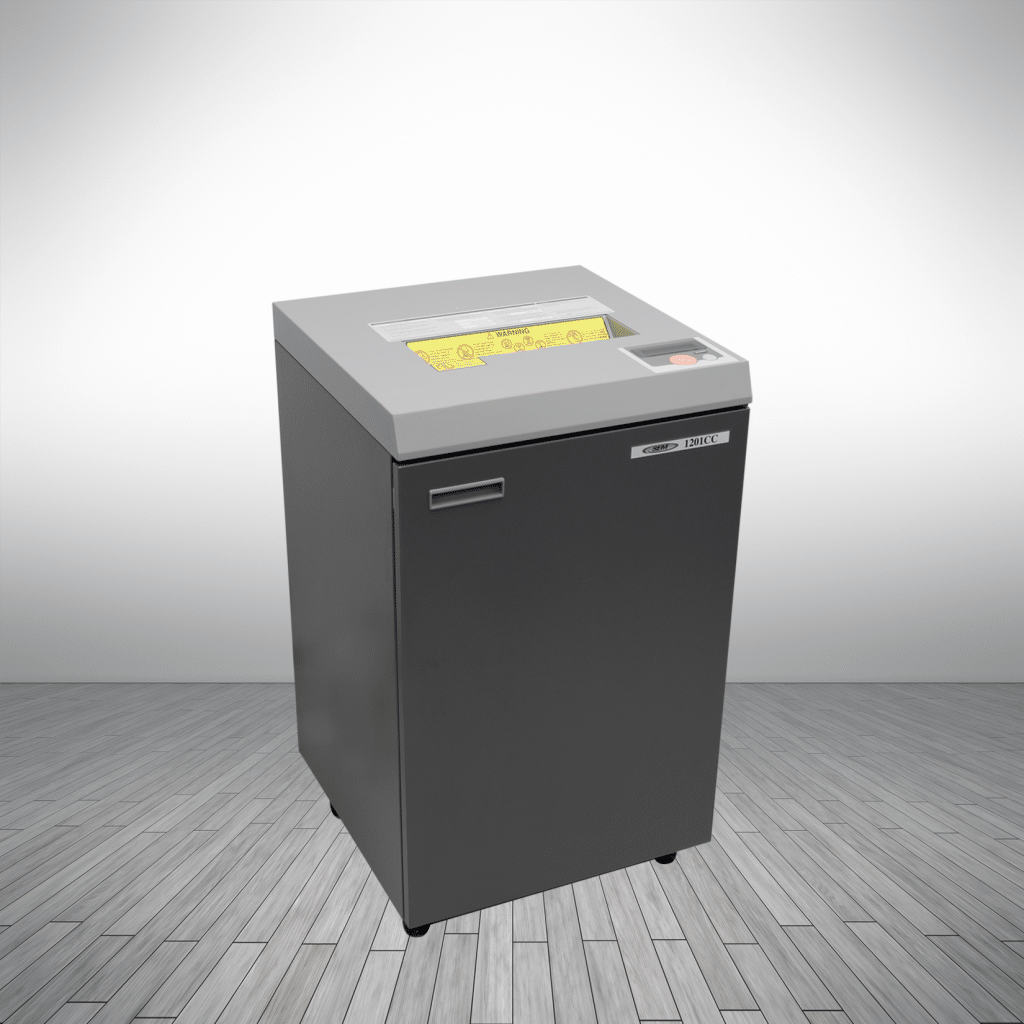

The F65 is a cousin of our very successful 1201CC NSA listed shredder that happens to be the only high security shredder on the market that does not require oiling. The 1201CC and F65 share the oil-free feature saving you money buying oil and preventing oil stained carpets for the life of the machine. Because of the innovative design and construction of the shredder mechanism, your F65 will never need oil — or jet fuel!

This shredder also offers several highly advanced features such as the waste compression fan press to optimize waste storage so you have to change fewer bags, LED panel with auto start/stop and reverse, bag full/door open indicators with auto stop, capacity control illumination bar to help prevent over feeding the machine, safety protection system (includes top access and e-STOP button), energy saving mode that shuts off power when not in use, rugged metal cabinet with casters for easy relocation/mobility, and TAA compliance.

So, if you need a shredder that can deliver a payload of shredding capacity that will inflict maximum damage to your backlog, the F65 will ensure your mission is accomplished!

Some guidelines to help you decide.

Some guidelines to help you decide. In 2003, the National Security Agency (NSA) added durability testing to all shredders being considered for their cross-cut shredder

In 2003, the National Security Agency (NSA) added durability testing to all shredders being considered for their cross-cut shredder

Look through a catalog or web site for high security information destruction devices and you’ll find so many types of machines: shredders, disintegrators, crushers, grinders, and more. Some machines handle one type of material, like just CDs and DVDs for example. Other machines destroy two or more kinds of media.

Look through a catalog or web site for high security information destruction devices and you’ll find so many types of machines: shredders, disintegrators, crushers, grinders, and more. Some machines handle one type of material, like just CDs and DVDs for example. Other machines destroy two or more kinds of media.